CMMS for Energy & Industrial

Equipment failures cause safety incidents and financial losses

No systematic way to predict and prevent failures

Breakdown root causes are not tracked or analyzed

Critical spare parts availability is uncertain

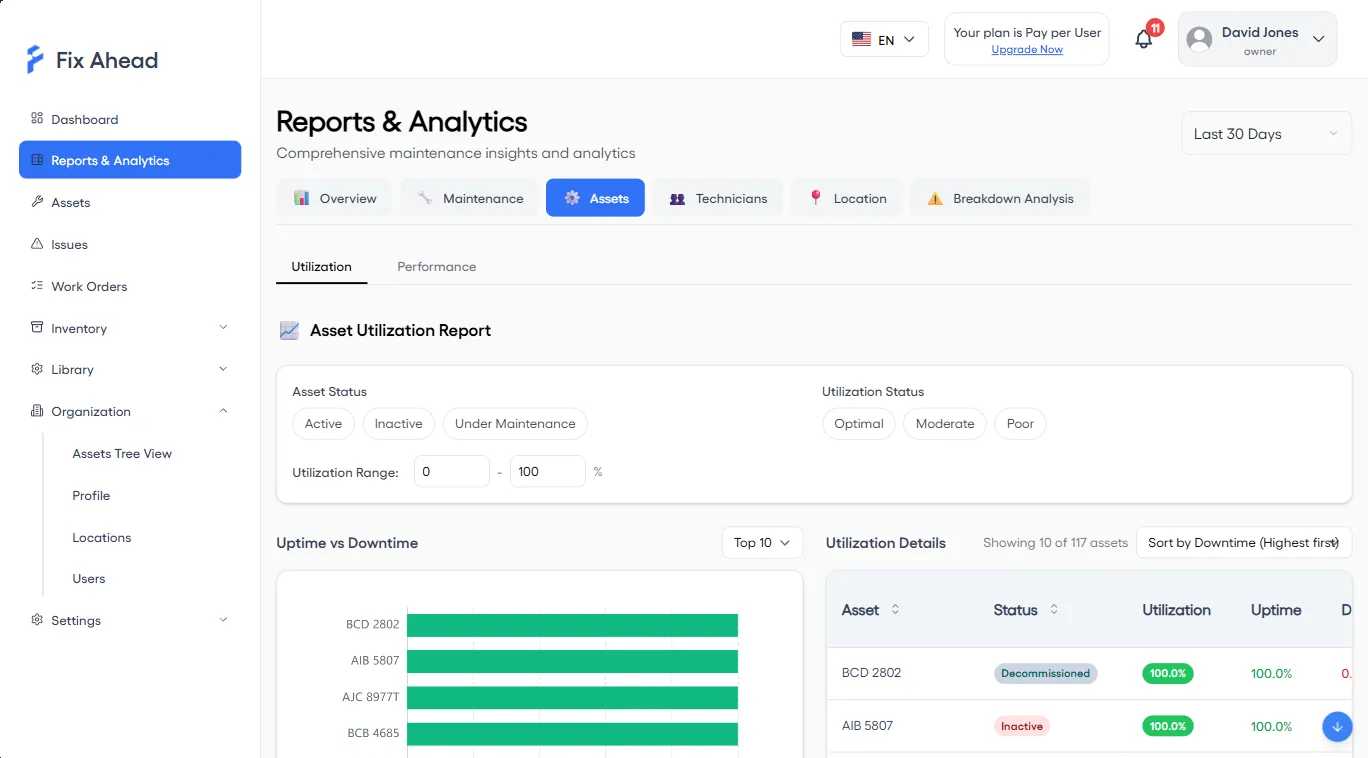

Track equipment reliability with precision

MTBF, MTTR, total breakdowns, uptime hours, and reliability percentage per asset. Identify which equipment needs replacement versus increased maintenance investment.

- MTBF and MTTR per asset and category

- Uptime/downtime breakdown with trend analysis

- Criticality levels: Critical, High, Medium, Low

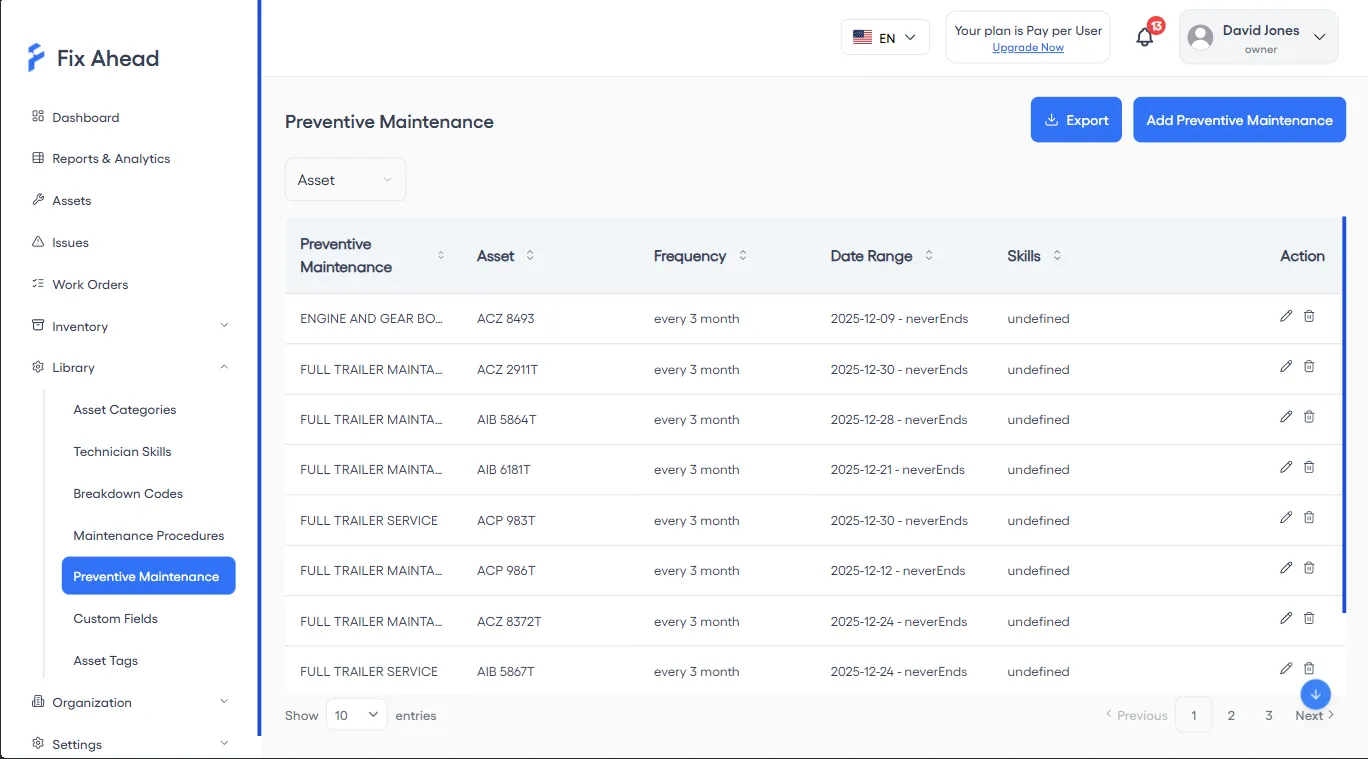

Prevent failures with scheduled maintenance

Schedule inspections, oil changes, filter replacements, and calibrations at manufacturer-recommended intervals. Auto-generate work orders with procedure checklists for consistent execution.

- Manufacturer-recommended maintenance intervals

- Auto-generated work orders with linked procedures

- PM compliance tracking per asset and schedule

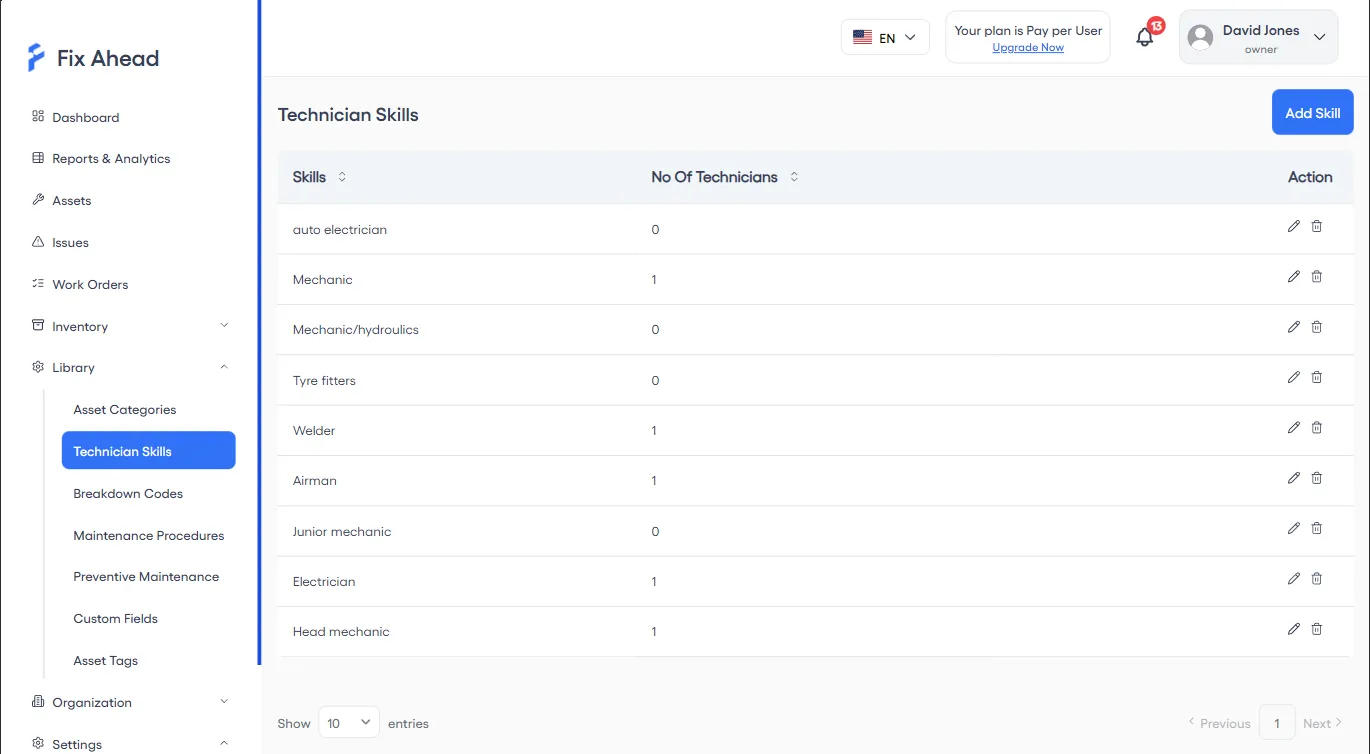

Specialized technicians for critical equipment

Register technician skills — electrical, mechanical, instrumentation, welding — and match them to PM schedules. Ensure only qualified personnel work on critical equipment.

- 9 registered skill types for precise matching

- Skill requirements per PM schedule

- Auto-suggest qualified technicians for assignments

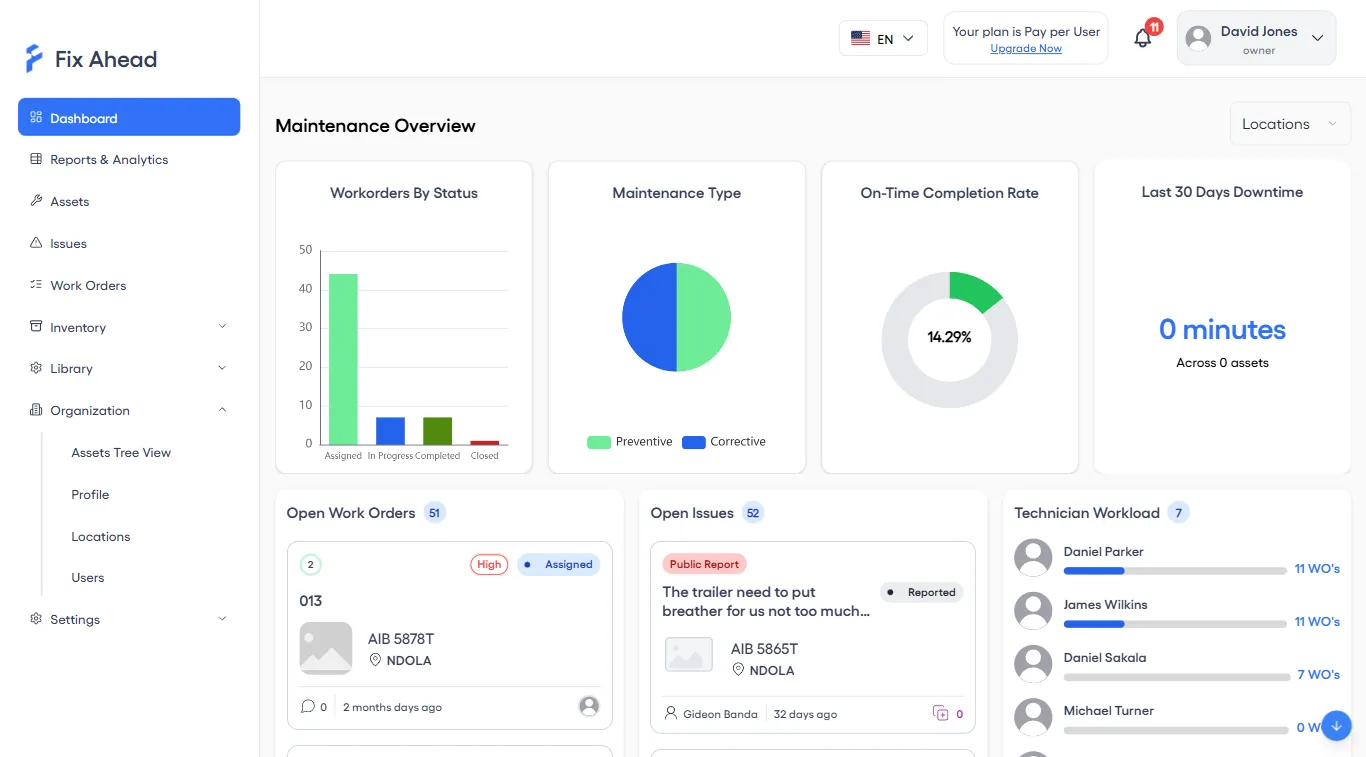

Scenario: Power Plant Equipment Reliability

A power generation facility classifies every equipment failure with breakdown codes — bearing failure, overheating, electrical fault, corrosion. Root causes are identified on work order completion.

- Breakdown analysis report visualizes failure type distribution

- Asset reliability reports show MTBF, MTTR, and reliability percentage

- Critical spare parts tracked with reorder points

- Specialized parts linked to qualified suppliers with lead times

Breakdown CodesRoot Cause AnalysisBreakdown Analysis ReportAsset ReliabilityInventorySupplier ManagementParts TrackingPreventive Maintenance