CMMS for Manufacturing

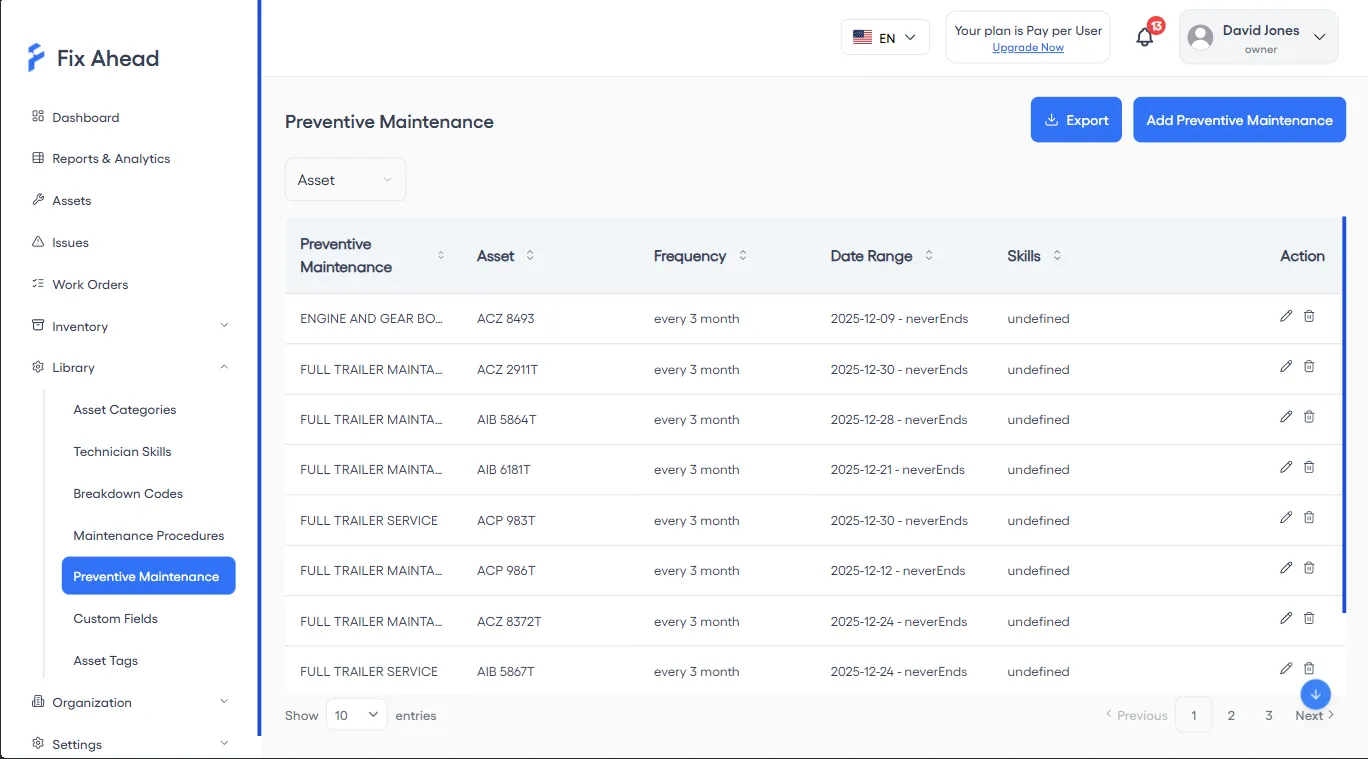

Automate preventive maintenance for every machine

Schedule weekly lubrication, monthly inspections, and quarterly overhauls. FixAhead auto-generates work orders days in advance so technicians are prepared — not scrambling after a failure.

- Recurring PM schedules at any frequency

- Auto-generate work orders before due dates

- Procedure checklists with photo evidence for compliance

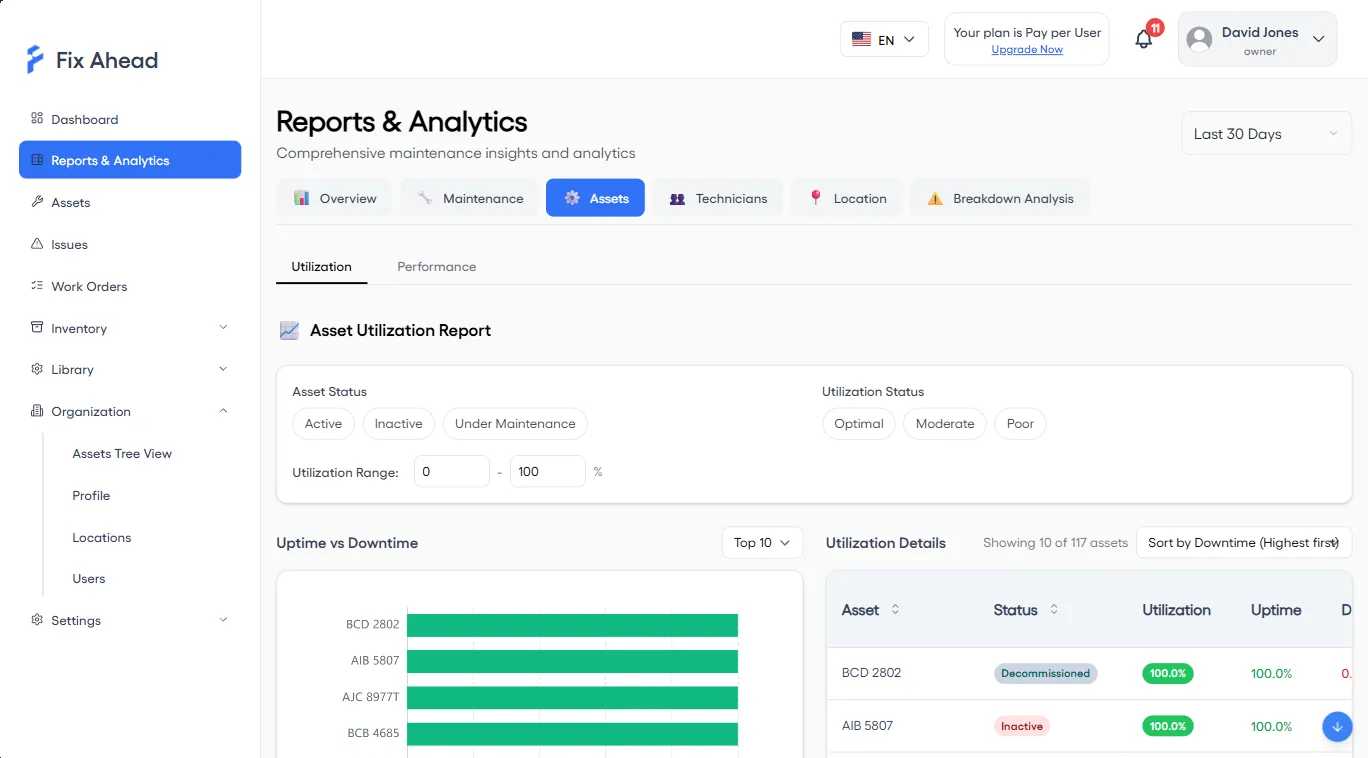

Identify your most unreliable equipment

MTBF and MTTR analytics pinpoint which machines break most often and how long repairs take. Breakdown analysis classifies failures by root cause — so you fix the pattern, not just the symptom.

- MTBF identifies failure-prone equipment

- MTTR tracks repair efficiency over time

- Breakdown codes classify failure types and root causes

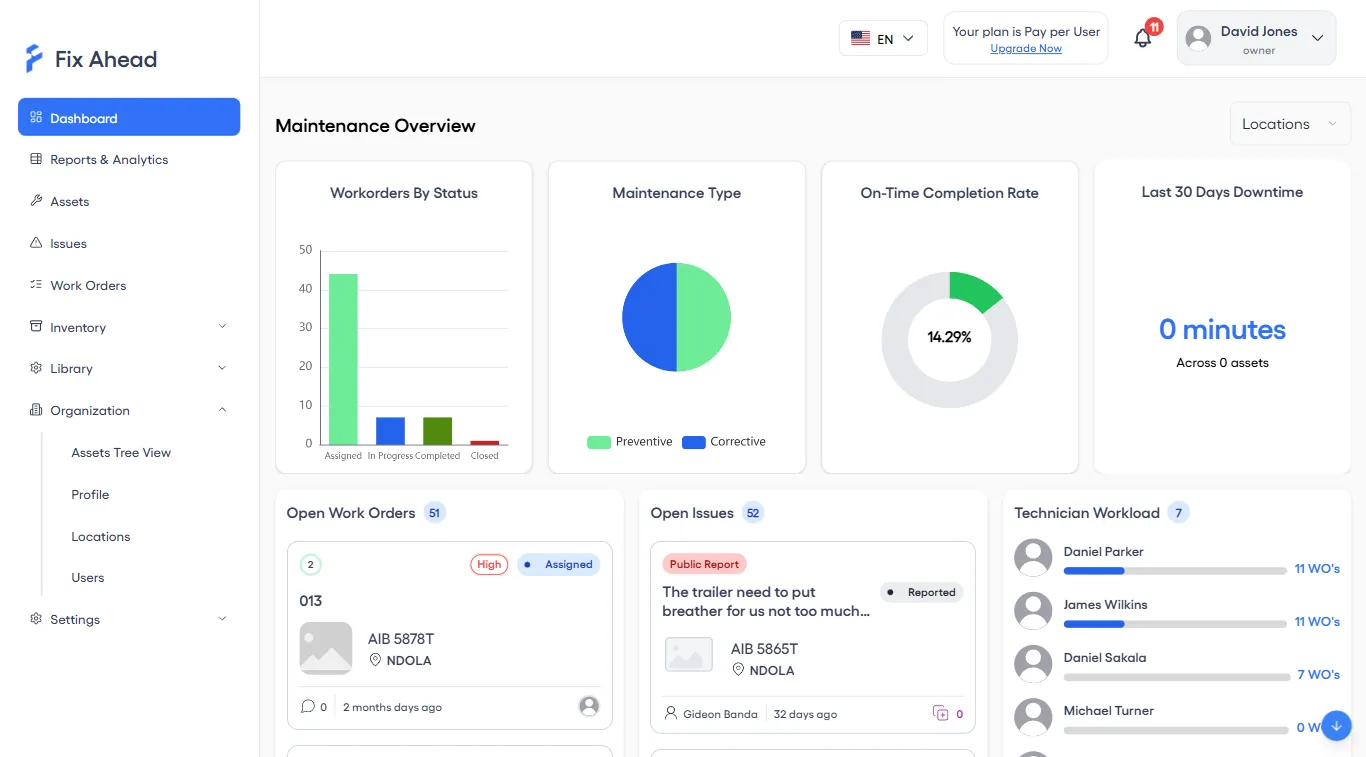

Real-time production floor visibility

Your maintenance command center shows work order status, on-time completion rate, technician workload, and open issues — all filterable by production line or location.

- Dashboard KPIs for production floor managers

- Filter by location to see per-line performance

- Track PM compliance rates to prevent missed inspections

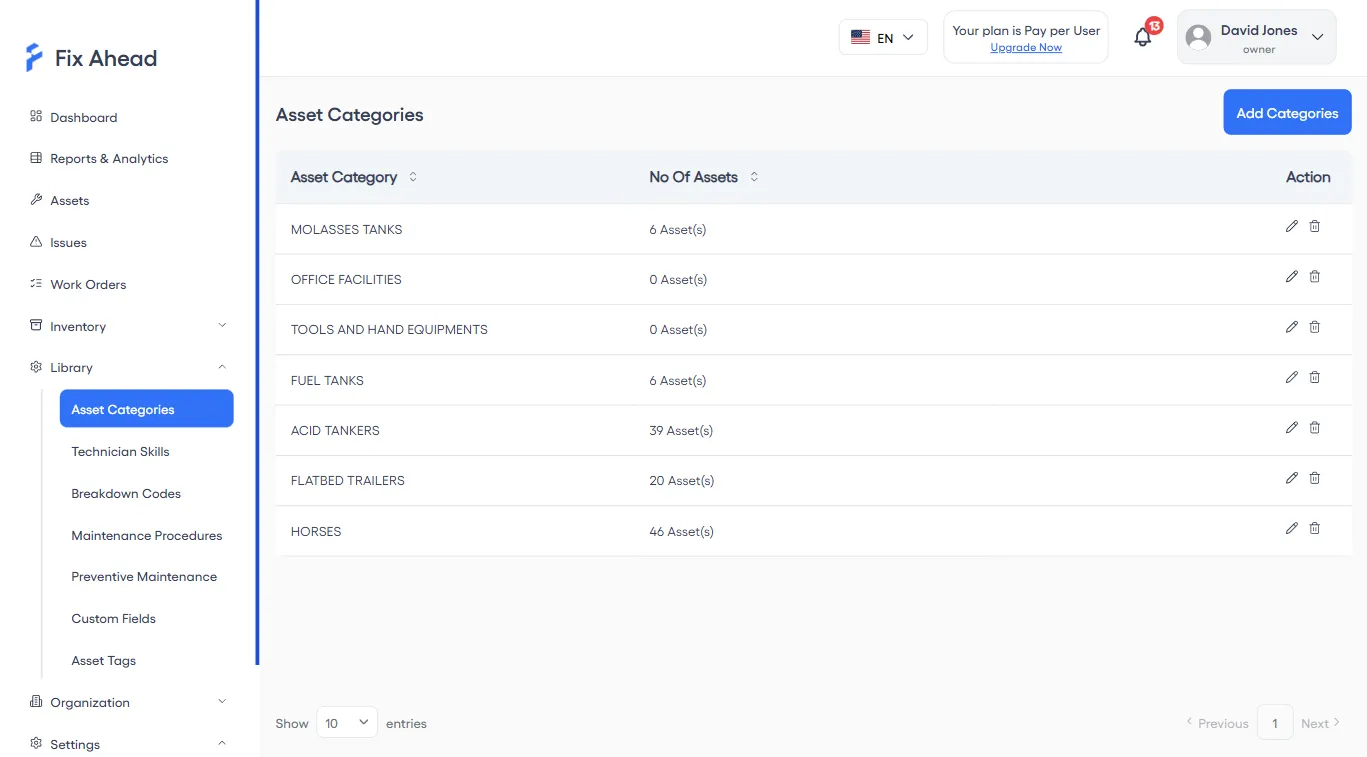

Scenario: Production Line Equipment Maintenance

A manufacturing plant runs 50+ machines across 3 production lines. Every machine is cataloged with custom fields — operating hours, RPM range, last calibration date. Preventive maintenance auto-generates work orders days in advance.

- Reliability reports identify the most unreliable machines

- PM compliance tracking ensures nothing falls through the cracks

- QR codes on every machine let operators report issues instantly

- Parts tracking ensures critical spares are always in stock